ChatGPT said: How to customize your apparel with 10:9 Design Screen Printing in 3 easy steps

The Crucial Overview to Recognizing Screen Printing and Its Versatile Uses

Screen printing has a rich history that dates back to old times, progressing right into an innovative strategy made use of throughout numerous sectors today. This overview explores the intricacies of the screen printing process, outlining its applications in fashion, home, and advertising décor - 10:9 Design Company. Recognizing these principles can open creative potential for both artistic and industrial jobs. The following areas will certainly reveal important pointers and methods to improve one's screen printing endeavors

The Background of Screen Printing

Screen printing has roots that trace back centuries, its development shows the imaginative and technical advancements of different cultures. Coming from ancient China, the technique was at first used for enhancing textiles and later spread to Japan, where it came to be indispensable to Ukiyo-e woodblock printing. The approach changed to Europe in the 18th century, where it got popularity among craftsmens and industrial printers. The invention of photo solution in the 20th century changed screen printing, permitting for more elaborate layouts and higher efficiency. Musicians like Andy Warhol better drove its appeal, using the medium to create iconic works that mixed commercialism and art. By the late 20th century, screen printing had actually developed itself as a versatile technique, utilized in vogue, marketing, and great art. Today, it proceeds to advance, integrating electronic innovation and expanding its applications throughout numerous sectors.

The Screen Printing Refine Explained

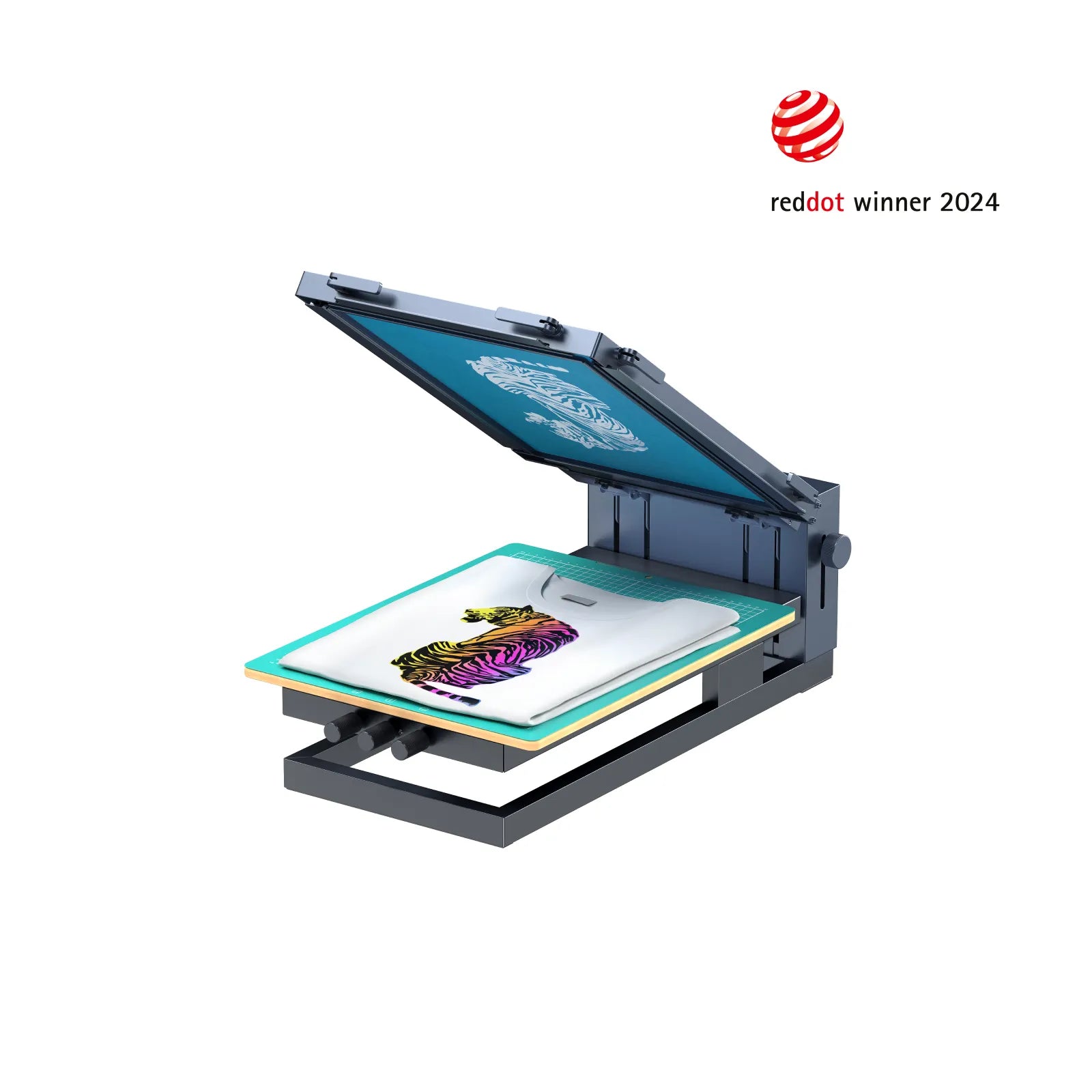

Screen printing transforms creative visions right into substantial designs with a series of specific actions. Initially, a photo is developed and after that transferred onto a screen, typically made of fine mesh textile extended over a frame. A light-sensitive solution is applied to the screen, which is subjected to light, hardening in locations not covered by the photo. After rinsing the unhardened solution, a pattern is formed.

Next, the screen is put over the substratum, whether it be material, paper, or an additional product. Ink is then pushed with the open locations of the stencil making use of a squeegee, transferring the style onto the substrate below. This process can be duplicated for numerous shades, calling for different screens for each tone. Finally, the printed thing is healed making use of heat to assure the ink sticks effectively, causing a resilient, lively layout on-line.

Kinds of Screen Printing Techniques

In addition, specialized techniques, such as discharge screen printing, get rid of color from the material to create softer prints, while aluminum foil screen printing applies metallic foil to accomplish a glossy coating (10:9 Design contact). Each method provides unique qualities, accommodating different creative demands and production ranges, ultimately increasing the opportunities within the screen printing domain

Applications of Screen Printing in Numerous Industries

Furthermore, the signage and advertising markets make use of screen printing for developing eye-catching displays and banners. This technique enables for bold colors and detailed layouts that catch focus. In electronics, screen printing is employed for applying conductive inks to circuit card, vital for element connections. The home décor industry welcomes screen printing to generate distinct designs on textiles and wall surface art. On the whole, screen printing functions as a critical tool throughout diverse areas, boosting products with individualized and visually attractive graphics.

Tips for Successful Screen Printing Projects

While embarking on a screen printing task, mindful attention to detail can significantly enhance the last result. First, picking top quality products is essential; this consists of the screen, inks, and substrates. Using ideal mesh counts can affect ink deposition and information resolution. Prep work is just as crucial; comprehensive cleaning of screens and appropriate exposure times guarantee crisp prints.

Next, accurate enrollment is important for multi-color prints. Using placement devices can assist attain exact layering. Furthermore, testing prints on scrap materials before production helps determine possible problems without throwing away resources.

Often Asked Inquiries

What Products Are Ideal for Screen Printing on Textile?

Cotton and polyester blends are perfect for screen printing on material because of their longevity and ink absorption. Furthermore, specialty textiles like silk or canvas can generate one-of-a-kind appearances and surfaces, boosting the overall style high quality.

How Do I Tidy and Maintain Screen Printing Tools?

To cleanse and maintain screen printing devices, one must frequently wash screens with suitable solvents, check mops for wear, lubricate relocating parts, and store all things in a dry, dust-free atmosphere to extend their lifespan.

What Are the Environmental Influences of Screen Printing?

Screen printing can have significant ecological influences, including chemical waste from solvents and inks, water usage during cleaning processes, and energy intake. Environment-friendly products and lasting techniques are essential for minimizing these unfavorable effects.

Can Screen Printing Be Done in your home Successfully?

Screen printing can be successfully done at home with the right products and strategies. Enthusiasts can create high quality prints, though success depends on their ability degree, devices, and understanding of the procedure included.

What Are the Prices Related To Starting a Display Printing Service?

Beginning a screen printing service entails expenses for tools, products, and office. First costs typically vary from a couple of hundred to several thousand dollars, depending on the scale, top quality of equipment, and desired manufacturing ability.

Screen printing has a rich history that dates back to old times, advancing into an innovative website strategy used throughout numerous sectors today. One more technique, rotary screen printing, utilizes cylindrical screens, assisting in continual printing on material rolls, therefore enhancing performance for large productions. In addition, specialized strategies, such as discharge screen printing, get rid of dye from the fabric to produce softer prints, while foil screen printing uses metal aluminum foil to achieve a glossy coating. In the style market, screen printing is commonly utilized to develop vibrant layouts on clothing, allowing brand names to showcase their special styles. Cotton and polyester blends are optimal for screen printing on textile due to their longevity and ink absorption.